Neodymium magnets - The complete guide: What is Neomagnets?

Neodymium magnets sound extremely high-tech, and they are! But you most likely have multiple items with them in your own home. These strong magnets are used in items from televisions to cell phones, and are the strongest commercial magnet today.

What is a neodymium magnet?

A neodymium magnet is a type of rare earth magnet. They are a permanent magnet, which means it can last for years and years. It is made up of an alloy of neodymium, born, and iron, and the most commonly used of the rare earth magnets.

It is the strongest type of permanent magnet that is commercially available to consumers, and is also extremely affordable to the average person.

The other kind of rare earth magnet is samarium cobalt, which is more expensive but handles higher temperatures much better. Because of this, though it is quite a bit more expensive and less strong, it is an important magnet to consider especially in industrial applications.

There are good applications for both types of rare earth magnets, but due to it’s power and price point neodymium magnets have become more popular, which brings us to our topic of discussion today. Keep reading to find out everything you need to know about Neodymium Magnets.

Related products - Neodymium magnets - The complete guide: What is Neomagnets?

-

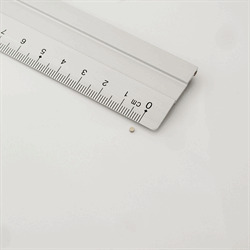

Power magnet, Disc 2x1 mm.

MAGZ-076-P

Strength 130 g. 0,56 0,70 EUR

In stock -

Power magnet, Cube 12x12x12 mm.

MAGZ-123-P

Strength 6.3 kg. 4,72 5,90 EUR

In stock -

Rubber magnet, Disc 22x11 mm.

MAGZ-043-R

Strength 7.1 kg. 5,40 6,75 EUR

In stock -

Power magnet, Disc 35x5 mm.

MAGZ-189-P

Strength 12.0 kg. 6,24 7,80 EUR

In stock -

Power magnet, Disc 20x10 mm.

MAGZ-116-P

Strength 11.0 kg. 6,36 7,95 EUR

In stock -

Power magnet, Disc 30x10 mm.

MAGZ-400-P

Strength 20.0 kg. 9,68 12,10 EUR

In stock -

Power magnet, Dics 60x5 mm.

MAGZ-413-P

Strength 22.0 kg. 20,00 25,00 EUR

In stock -

Power magnet, Block 60x30x15 mm.

MAGZ-141-P

Strength 56.0 kg. 26,32 32,90 EUR

In stock

Neodymium magnets are also known as NIB, NdFeB, or Neo magnets. They are a type of rare earth magnet, which just means they are part of the rare earth element classification of which there are seventeen elements.

| Magnet | Neodymium (NIB, NdFeB, or Neo Magnets) |

| What it’s made Of | Rare-Earth Elements (Neodymium) |

| When it was created | 1980s (first used in General Motors) |

| Grades | N45 (most common) - N55 (most quality) |

These seventeen elements are made up of fifteen lanthanides, in addition to scandium and yttrium. These last two elements are considered rare earth elements because they often end up in the same deposits of ore as the other fifteen elements, and they also have very similar properties.

Neodymium magnets were first developed in the 1980s. General Motors along with Sumitomo Special Metals were researching alternatives to samarium cobalt due to the prices being driven up, and managed to create the tetragonal crystalline Nd2Fe14B.

General Motors focused on something called bonded neodymium, as well as isotropic Neo powder. Sumitomo focused more on sintered neodymium. These two types of neodymium magnets are extremely different implementations of the compound.

Bonded neodymium magnets are usually only about half as strong as sintered magnets are. These magnets are also often less expensive due to the process of creating them.

Bonded neodymium magnets can be made into almost any imaginable shape and size. To make bonded versions of these magnets, the materials are mixed using epoxy as their binder, pressed into a die and then cured using heat.

These magnets are much different than sintered, as they don’t have a grain for their magnetic field, and they also are much sturdier than sintered magnets.

Sintered neodymium magnets have a much higher strength than their bonded counterparts. However, they are more brittle, and also cannot be made into as many shapes and sizes.

Rather than the epoxy process used to create bonded neodymium magnets, the alloy is milled to an extremely fine powder, then compacted using pressure. It is compacted within a magnetic field, which gives it a specific direction of magnetism. There is also a complex heating process involved.

There are multiple grades of neodymium. To understand grades of these magnets, all you have to do is pay attention to the number.

The higher the number, the higher the grade. While a higher grade means that the magnet has much more power, it also means that the magnet is more brittle. The more common grade of neodymium magnet is N42, but the highest grade is N55.

N55 has a very low operating temperature and is comparably extremely expensive, so it only has use in very specific applications. In order to create this extremely concentrated magnet, the company making it does not add any complementary heavy rare earth elements.

This means that the highest temperature that these magnets can be used at is the very low 140 degrees Fahrenheit. Because of this and it’s exponentially higher price, it isn’t commonly used.

Neodymium magnets are popular among other permanent magnets for a variety of reasons. They are extremely powerful, even compared to similar magnet types. This allows for very small magnets to still be efficiently used. We see this often in things like jewelry clasps.

While neodymium is already cheaper, the ability to use smaller magnets enhances this. It is also important to remember that the average consumer isn’t going to need a high grade of magnet, which significantly reduces the cost as well. Ceramic permanent magnets are cheaper, but only are a fraction of the strength.

Permanent magnets are magnets that last an extremely long time before becoming demagnetized.

Neodymium is also good at resisting outside sources of demagnetization, like other magnetic fields. In the case of sintered neodymium magnets, they will remain magnetized practically indefinitely, losing less than 1% of their power over 100 years!

Neodymium magnets do have some downsides, as they don’t handle higher operating temperatures as well as other types of magnets sometimes can.

They also are brittle, though a lot of comparable magnets are as well. They can oxidize and corrode easily as well, which is often combated by a protective coating of nickel or a copper nickel mixture, sometimes even multiple coatings.

This measure of heat tolerance is called the Curie temperature, and this measures the temperature where the magnets start to fail and become demagnetized. Because of this, often samarium cobalt is used instead in cases where the magnet needs to perform in high heat.

Neodymium is also prone to corrosion, especially within the grain of the sintered variety of magnet. Often to combat this, these magnets are coated. A few common coatings are a copper and nickel combination, and nickel. These coatings are also sometimes applied multiple times for extra protection.

Other coatings that are sometimes used are rubber, epoxy, zinc, gold, tin, and titanium. Each has their own application, for instance in outdoor use a combination of epoxy, nickel, and copper can be used.

Properties of neodymium magnets:

- Has a very high strength magnetic field, as well as high density of it’s magnetic energy

- Is cheaper, especially when you consider that you can use a smaller magnet

- Great at resisting demagnetization, and is considered a permanent magnet

- Lower heat tolerance (Curie temperature) in comparison to other permanent magnets

- Corrodes easily, and can be brittle

When using rare earth magnets like neodymium, it is important to remember that they need to be handled safely. They are extremely powerful, and because of that can harm the user in multiple ways if not properly used.

Getting skin or a body part stuck between two strong magnets, or a magnet and a magnetic surface, can result in injury. Shockingly, if the magnet is large enough, this can even break bones!

Since these magnets are brittle, it is also important to think about the potential of flying shards. If they accelerate towards another magnet, or a metal surface, it is entirely possible for it to shatter sending sharp metal everywhere.

Also, while creating these magnets requires a plethora of safety equipment, you shouldn’t have to worry about the toxicity of them unless ingested. Ingesting magnets is always very dangerous, and because of this these magnets should stay far out of the reach of children.

What a neodymium magnet is made out of

The composition of neodymium magnets differs dramatically on the grade of the magnet. First, of course, they contain neodymium, which is the rare earth metal.

In addition, they contain a large portion of iron to try and prevent corrosion, though we know they still are prone to it. boron is also added, mainly as a bonding agent.

If you want to imagine the bonds visually, think of a row of iron, followed by a row of combined neodymium and boron.

In addition to these main three components, other elements such as dysprosium and praseodymium may be added to help increase the resistance to corrosion. It is also common to add cobalt to help performance at high temperatures.

Common ingredients in neodymium magnets:

- Neodymium (Nd)

- Boron (B)

- Iron (Fe)

- Dysprosium (Dy)

- Praseodymium (Pr)

- Niobium (Nb)

- Aluminum (Al)

- Cobalt (Co)

Usually when creating these magnets, they go through a specific creation process. Though this process differs depending on magnet type, the sintered neodymium magnet process is one that is particularly interesting.

The chemicals, once properly weighed and combined, go through a chemical reaction. These chemical reactions often occur in a vacuum induction furnace, which uses electric currents to melt metal in a vacuum. This can help keep the ingredients free from any outside elements or contaminants.

Once the chemicals have been melted, they go through a process called jet milling. Jet milling grinds materials through a high speed compressed air or gas. This allows for extremely small particle sizes!

Next, the powder gets pressed into a die. It actually gets pressed twice, which is what allows the preferred direction of the magnetization. It ends up being parallel to the direction it was being pressed.

Once this first pressing step is done, we still don’t have a solid magnet yet. The pressed powder is heated hot enough so that it will adhere to itself, but won’t turn into a liquid. This temperature can sometimes be nearly 2000 degrees Fahrenheit depending on the metal!

Now that the magnets are more solid, they are cut to the shape needed for their use. This process is called machining. This helps define their exact shape.

The next step to this process is to add a coating if needed. Common coatings are either a copper and nickel mixture, or solely nickel. These coatings help prevent the corrosion that neodymium is so prone to.

At the very end of this process, the magnets has to be magnetized! There are different methods to do this, but it always involved exposing the magnet to a very heavy magnetic field in order to charge them.

What is a neodymium disc magnet?

Neodymium disc magnets are a version of the magnet that is shaped like a flat disk, the thickness is not larger than the diameter of the circle. This is one of the most popular shapes sold.

This is partially due to their convenient ability to fit into other crafting components. Examples of these would be tubes, drilled holes, and within rings.

These shapes of magnets have a lot of great uses, such as within any craft project, as sensor magnets, within motors, in common electronics, and even as medical magnets.

There are some extremely common uses for this type of magnet, and you probably use them without noticing.

Uses for neodymium disk magnets:

- Fridge magnets

- Closures in place of buttons, such as on a purse clasp

- Magnetic therapy, which is said to help with migraines, breathing, and muscle issues (though there isn’t scientific evidence of this)

- Speakers

- Within toys and games to hold pieces

- Key holders or tool holders

Though larger disk magnets are used industrially, many use things like aluminum coils, An interesting application for these types of magnets are the large industrial disc magnets that are used to pick up items within junkyards. Many of these magnets have a magnetic field of around 1 tesla!

How are neodymium magnets used?

Due to their strength and price, neodymium magnets are heavily used in multiple applications.

They are used often for home crafts, providing things like magnetic closures for cabinets, or clasps for various bags and clothing. Besides home craft use, however, they are used in a variety of other forms.

Uses for neodymium magnets:

- Around the home for magnetic closures

- Within clothing and accessories

- In MRI machines

- Sound equipment

- Magnet therapy

- Hard Drives

- Dentures

- Space technology

- Cell phones

Magnetic resonance imaging, more commonly known as MRIs, are medical devices used to capture images of your body without using radiation.

This amazing medical device uses neodymium magnets to help analyze the inside of the human body without radiation.

The technology behind these machines are fascinating, the magnets are able to touch the electrons within your body, and then is able to take a picture of the effects of the magnet’s touch!

This procedure is amazing, and used constantly in medicine as it doesn’t use harmful radiation to capture the image.

A very common use for neodymium magnets is within audio technology. Speakers using this technology use an electromagnetic coil placed in front of the neodymium magnet.

Electricity is pushed through the coil, and the permanent magnet at the end causes the field to change rapidly as it is attracted and then pushed away from the neodymium magnet.

Magnet therapy, as previously mentioned, isn’t scientifically proven to help relieve any issues like pain or breathing issues. With that being said, bracelets with these magnets and other products are often sold at kiosks within malls, and you even can book entire magnet therapy sessions with a specialist.

Hard drives are both extremely complex, and amazingly simple. In your hard drive, there is a large magnetic plate that stores data. The way it stores data is by assigning each of it’s tiny parts a specific number, a one or a zero.

These numbers represent something very simple, whether the section is magnetized (one) or not magnetized (zero). The drive is able to translate your data into these ones and zeros.

This is one of the many reasons why it is always said that you should keep magnets away from your any technology that stores data – if you mess up the magnetization within your hard drive, it can ruin your data immediately.

Believe it or not, neodymium magnets were used on the Mars Exploration Rovers. When these robots were traversing mars, part of their mission was to collect and look at the dust on mars.

The rovers had a brilliant setup. One set of magnets was carried by a cutting arm called the rock abrasion tool. This was used to drill into rocks for proper inspection. There were also two other locations with neodymium magnets, one was on the top of the rover to keep dust that was blown around off of the top of the rover.

The other group was towards the front, and it was angled so that mostly magnetic materials would stay on the top of the magnet. There were then tools to look at what stayed on the magnet.

Chances are, you know exactly what a cell phone sounds like when it vibrates. That noise and shaking is usually caused by a motor in your phone that uses a neodymium magnet! This is also the case for other similar vibrating tools like pagers.

Recently, neodymium magnets have been used within toys. Many small balls of these magnets are sold as a set, and can be used to build structures and make patterns and shapes. While a fun toy for older children, it is important to keep these small ingestible magnets away from smaller children that may eat them.